News Story

Wells Fellowships Support New Battery and Catalyst Technologies

Above: Laleh Emdadi. Below: Chao Luo.

Department of Chemical and Biomolecular Engineering (ChBE) graduate students Laleh Emdadi (advised by Assistant Professor Dongxia Liu) and Chao Luo (advised by Associate Professor Chunsheng Wang) have received the University of Maryland Energy Research Center’s first Harry K. Wells Graduate Fellowships. The $20,000 awards, made possible by a $400,000 endowment from Harry K. Wells (B.S ’43, mechanical engineering), support graduate research in the field of sustainable energy generation or storage.

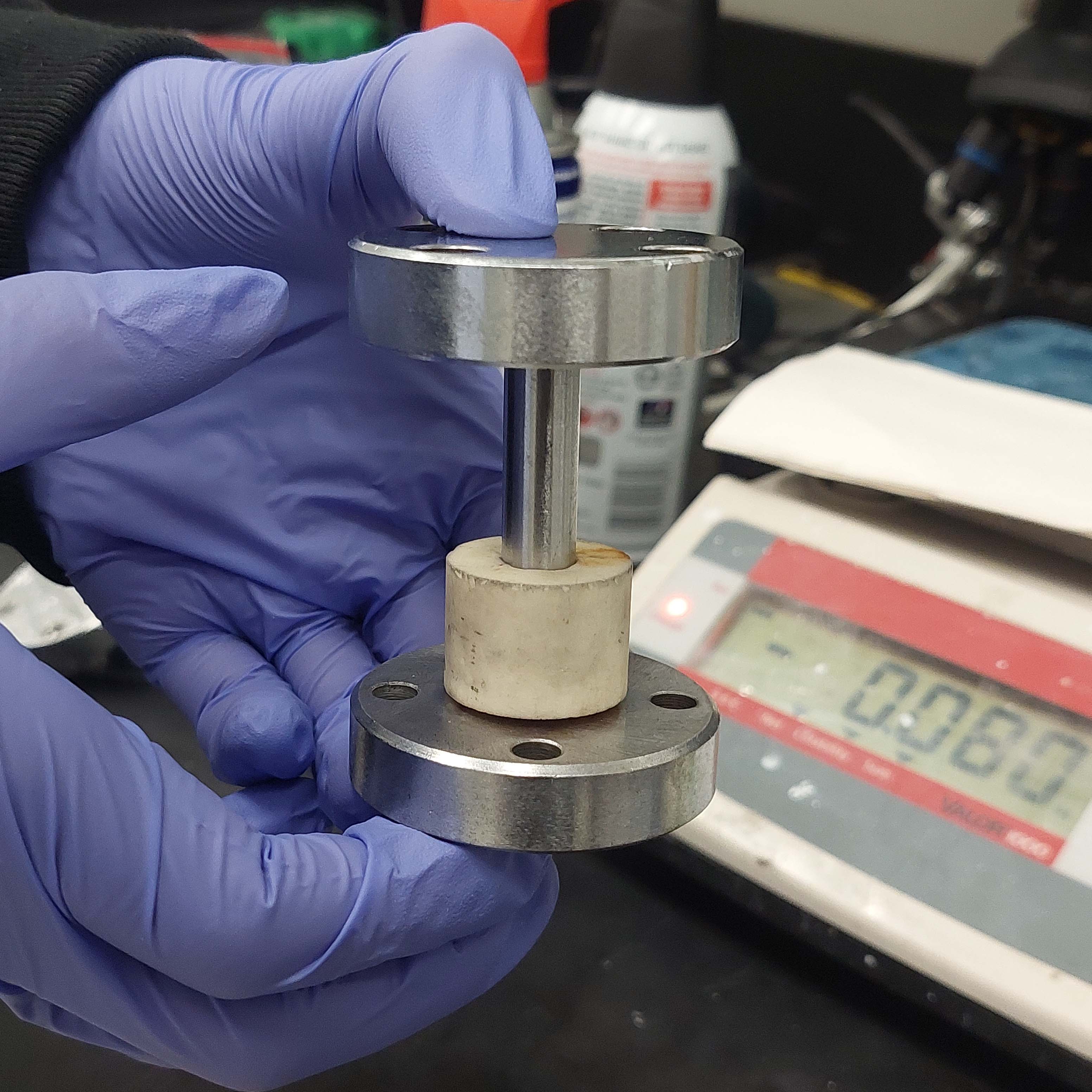

Laleh Emdadi: Fast, High-Yield Catalysts

Emdadi is searching for ways to improve the cascade reactions that convert biomass (plant matter) into the commodity chemicals used to make biofuels and other biomaterials. Cascade reactions are ordered, consecutive series of reactions, each facilitated by an inorganic or organic catalyst. This process, Emdadi explains, is complicated, expensive, and wastes energy because each reaction in the cascade requires its own cycle of separation and purification, and often its own type of catalyst.

“Instead of using these multi-step reactions,” she says, “we are designing a catalyst that is able to handle the whole cascade reaction at once.”

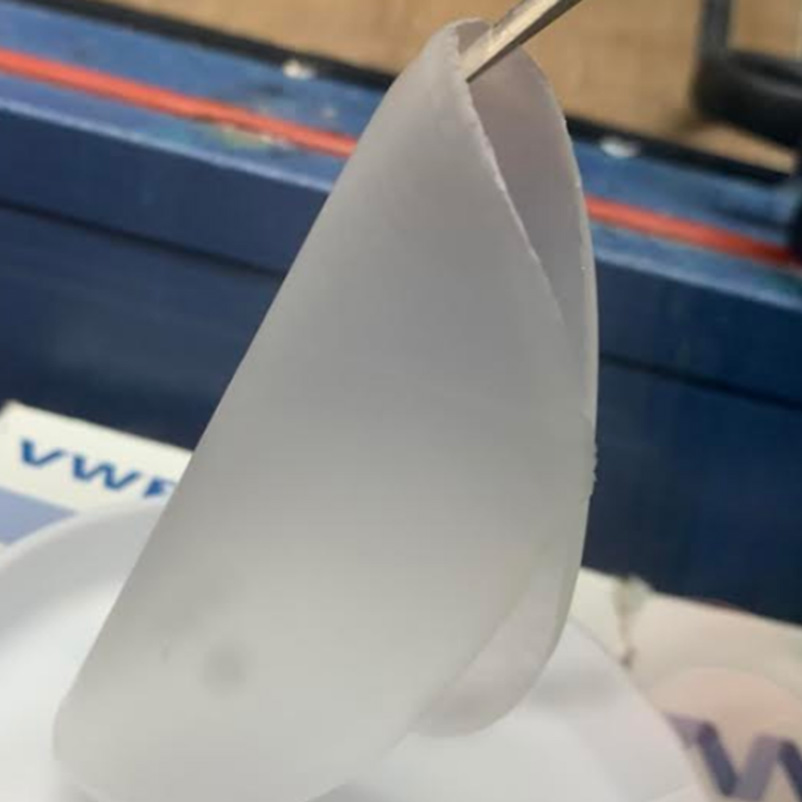

Emdadi’s catalyst is made from a very thin, plate-like zeolite. Zeolites are microporous aluminosilicate minerals that are already used in industry as catalysts and in separation processes. Emdadi and Liu are using their zeolites to build a novel catalyst structure in a way Liu compares to building a tower with bricks. The new catalyst will perform all of the reactions necessary to convert cellulose (the high-energy ingredient extracted from biomass to create fuels) into 5-(ethoxymethyl)furfural (EMF), which is used in the synthesis of biodiesel. Its advantages include enhanced mass transport, a high yield of desired products, and few unwanted byproducts. These attributes allow it to produce more EMF at a higher rate than traditional zeolite catalysts.

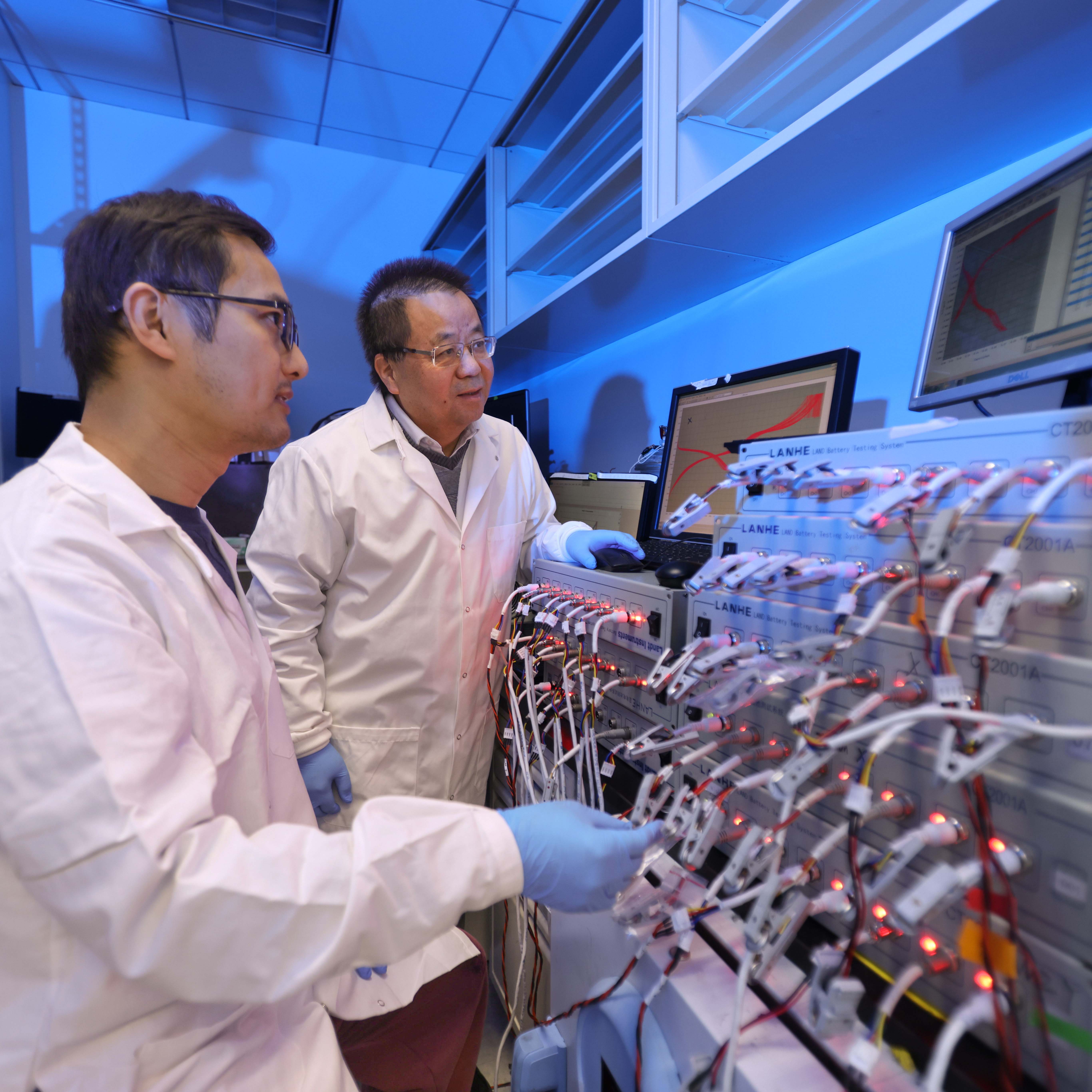

Chao Luo: Organic Battery Electrodes

Like many researchers, Luo is concerned about the future of rechargeable lithium-ion (Li-ion) batteries, due to their reliance on non-abundant materials, high cost, and a recycling process that consumes large amounts of energy and releases carbon dioxide.

“Next generation batteries should not only have high power and energy densities, but also be made from renewable and recyclable materials,” says Luo. “Organic materials derived from biomasses are the best candidates for lightweight, flexible, transparent batteries because of their sustainability, environmental benignity and low cost.” Luo would like to develop organic electrodes for Li-ion and sodium-ion (Na-ion) batteries. If commercialized, Na-ion batteries would provide a cheaper alternative to Li-ion technology.

Research on organic battery electrodes is still in its early stages, but Luo is excited about the possibilities—his project is currently unique on campus. The Wells Fellowship, he says, will enable him to synthesize several organic electrode compounds that he will test for electrochemical performance, and to acquire the detailed results he needs to pursue grants for further research and development.

In Luo’s preliminary work, he used organic croconic acid disodium salt as a main component of an organic electrode for Li-ion and Na-ion batteries. His results demonstrated that using nanoscale salt particles and coated with graphene oxide significantly enhanced the electrode’s performance in both types of batteries. The results have been published in Nano Letters and the Journal of Power Sources.

Published June 11, 2014